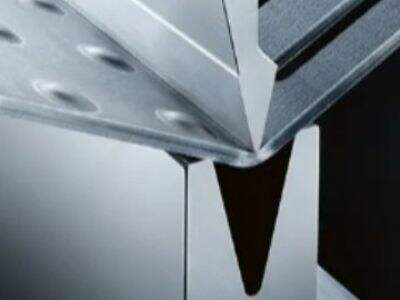

Wondering how metal being cut into every kinds of variety using this awe laser beam! The material we produce at JHW is sheet metal which has the specific cutting method that allows us to do so, laser cutting. It's this technology that enables us to deliver incredible pieces for just about any project

Laser Cutting Technology: Redefining Sheet Metal Fabrication

Different shapes and sizes, of cutting metal into depths was a very difficult job to do in the past that too a lot time and effort could be wasted. However, now with the laser cutting technology, we are able to cut through metal as if it were a piece of cake. It can cut through metal like a hot knife! What tool on Earth is more magical than the laser beam? This changed the way how we work with sheet metal and our products have become more accurate and efficient as well

Custom Sheet Metal Fabrication in the Future

Laser cutting technologySustainable future of custom sheet metal fabrication It allows us to produce highly detailed designs and patterns on demand, transforming your vision into reality. With state of the art laser cutters, we can do everything from a custom metal sign at your business to a custom piece for your home. There is no end to the possibilities, and just looking ahead at where this technology can carry us has us giddy-thinking of all the things to come

Innovations In Laser Cutting That Are Transforming The Design Spectrum

The technology of laser cutting has revolutionized sheet metal manufacturing and the way that we design and create sheet metal products. This means that we can now try all kinds of shapes, sizes and patterns which were previously outwith the realms of possibility. Even if they more than 10,000 locations and provide the same thing… It makes you unique so you can be creative in your projects to make different designs/projects that will sets example. Here at JHW, we are always learning, developing and creating new products that push the boundaries of design and what can be achieved with laser cutting technology

Laser Cutting Makes Production Process Easy For Sheet Metal Fabrication

Where laser cutting makes it incredibly easy to improve our production processes The metal became a needle and it would take longer to cut each individual piece of metal. However, with laser cutting this is possible because cutting can be done on multiple pieces simultaneously hence it saves time and streamlines our production process. By having a machine that works extremely fast through metal stamping it gives us the ability to complete projects quicker and without sacrificing quality at all, both of which we believe will you get your custom sheet metal products delivered faster on time

The Newest Innovations In Laser Cutting For Custom Metal Fabrication

As a leading provider of laser cutting for custom metalwork, we are always on the cutting edge at JHW. This enables us to invest in the latest technology and equipment, ultimately delivering you a quality product. No matter if it is a simple metal sign or a custom (yet intricate) piece, we have the tool and knowledge to make your vision. At LA Mobile we pride for our luxury of printing world known dirt style type 3D design and if you want the best sheet metall fabrication, then look no further than US

In short, laser cutting technology has transformed our approach to sheet metal work at JHW. Whether it be allowing for new methods of design to assisting in the simplification of production processes, custom sheet metal fabrication has been taken to another level by this technology. We will be exploring the vast world of laser cutting and in return creating beautiful products for our customers

Table of Contents

- Laser Cutting Technology: Redefining Sheet Metal Fabrication

- Custom Sheet Metal Fabrication in the Future

- Innovations In Laser Cutting That Are Transforming The Design Spectrum

- Laser Cutting Makes Production Process Easy For Sheet Metal Fabrication

- The Newest Innovations In Laser Cutting For Custom Metal Fabrication