The significance of CNC Machining serving micro precision metal parts

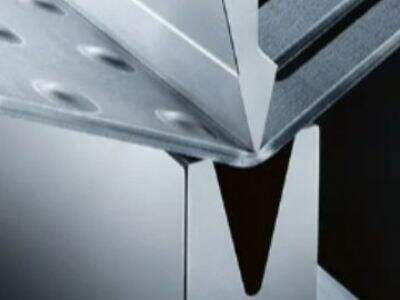

CNC machining is vital in the manufacture of micro-precision metal parts. These parts are very small and require a lot of precision and accuracy when they are being made. CNC machining makes it possible to produce metal parts with intricate and complicated details, which are required in industries like aerospace, medical and electronic industries. It would have been virtually impossible to produce parts as fine and delicate as these micro components without CNC machining. JHW recognizes the quality process CNC machining is important to the development of high precision metal components, with our modern industries' highest standards.

How CNC Machining Technology brings precision and accuracy in making of Metal Components

CNC based machining is a quantum leap forward in the manufacture of precision metal parts. CNC machining achieves consistent accuracy and repeatability with the aid of computer-controlled machines. This method opens up the possibility to produce complex shapes and patterns which would be difficult to achieve by hand. CNC machine can work at levels of perfection that are nearly perfect, making very accurate metal components. JHW utilizes CNC machining to improve the precision of its metal parts, making them achieve a higher standard than that offered by other industry players.

CNC Machining of High-Precision and Micro-Small Metal Parts - wholesale RTWF / NOW OFFICIAL Stockist

JHW, we are experts in manufacturing quality micro precision metal parts for CNC machining. CNC machining refers to the process in which computerised machines are used to remove materials from a work piece so that it becomes of the intended shape and size. This process enables us to fabricate complex and accurate metal parts in a tight tolerance range, and is well suited for industries including aerospace, automotive, and electronics.

With our ability to provide distribution box we can also give wholesale manufacturers the benefit of access to a valuable resource for dependable micro-precision parts. Our state of the art machines are capable of producing a high volume of components with little human influence resulting in quick turn around and cost effective solutions to our customers. For custom designed components or industry standard parts, we can service your needs with quality products and on-time delivery.

Quality inspection of CNC machined micro-precision metal parts At back history, we talked about DFM

Quality control is placed at our first priority when buying panel box from JHW. We strictly control the quality of our products at all levels and was down-to-earth to this. Our team of highly qualified machinists inspects each and every piece for dimensional consistency, surface finish and precision before we ship them to our customers.

For QC we have CMM and other high tech metrology instruments to check dimension for each piece. We also always perform preventive maintenance on our CNC equipment to insure nothing will effect the quality of the part being created. Plus we have plenty of dedicated quality control staff, they work in whole line to trace spares so can make sure product best quality.

Benefits of CNC machining Micro-Precision Metal Parts What are the Benefits of CNC Machining for Micro-component Metal Part Production

There are several benefits of using CNC machining to manufacture micro-precision metal parts at JHW. At its core, it is that CNC machining enables close tolerances and reliability – a need for ensuring that our parts are produced to your exact specs. Such precision is essential in industries that demand close tolerances and complex designs.

Benefits

And what’s more, CNC machining is an adaptable process that can fabricate a variety of metallic parts, ranging from basic designs to complicated shapes. This versatility enables us to service numerous industries and applications, creating tailor-made solutions for our customers specific requirements. Electrical board panel would be a relatively low cost method of production due to the saving of material, labor costs and thus is eco-friendly for our customers.

Conclusion

At JHW, CNC machining is an integral part of producing high quality micro-precision metal parts. Leveraging our state of the art technology, stringent qc standards and accommodating solutions with our thorough quality control operation The Perfect Part can provide wholesale for businesses in need of dependable and consistent metal parts. Contact us today and find out about our CNC machining services and how we can assist with your manufacturing requirements.

Table of Contents

- How CNC Machining Technology brings precision and accuracy in making of Metal Components

- CNC Machining of High-Precision and Micro-Small Metal Parts - wholesale RTWF / NOW OFFICIAL Stockist

- Quality inspection of CNC machined micro-precision metal parts At back history, we talked about DFM

- Benefits of CNC machining Micro-Precision Metal Parts What are the Benefits of CNC Machining for Micro-component Metal Part Production

- Benefits

- Conclusion